| ||||||||||||

| 1.Lab Ball Mil: | ||||||||||||

| Application & Process: | ||||||||||||

| The Laboratory scale Ball Mill is mainly used for various grind able materials dry or wet type in Chemical, Pharmaceuticals, Herbals and Catalyst Industries for super fine micron size grinding Prism Laboratory Scale Ball Mill is made from all the contact parts in S.S.316 & non contact parts in S.S. 304. The Drum Size: Dia 90 x 90 mm length cylinder type made from S.S.304 Quality. The drum is rotate on two nos. drive shaft and the shaft is rubber coated. The drum is having variable speed through Ac frequency drive for up to 60 RPM. The complete drive unit with motor and gear box is enclosed in structure and it is made from S.S.304Q. The Controls panel provided with ON-OFF push button, Speed regulator, RPM Meter and Process Cycle timer. | ||||||||||||

| New Design Features: | ||||||||||||

| ||||||||||||

| TECHNICAL SPECIFICATIONS: | ||||||||||||

| ||||||||||||

| ||||||||||||

|

Wednesday 9 March 2011

POWDER FINE GRINDING

MILLING AND SIZE REDUCTION

| ||||||||||||||||||||||||||

Multi Mill: | ||||||||||||||||||||||||||

| Application & Process: | ||||||||||||||||||||||||||

Table top Laboratory Multi Mill is used for wet and dry granulation in pharmacy colleges, R&D institutions and pharmaceutical industry for research and development of pharmaceutical products. It is a self contained portable unit useful for granulating, pulverizing, mixing and size reduction. The Multi mill operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the required size reduction. The material is fed in the hopper, shredded and milled through beaters consisting of knife and impact edges. The rotation speed and direction of beaters could be adjusted through control panel. The material then passes through the cylindrical screen in spiral motion which helps keeping the temperature low and avoids chocking of material during the process. The material is collected in the container placed under the hopper. In multi mill particle size reduction is done through impact in air, on material by blades moving at high speeds, inside a cylindrical hopper. | ||||||||||||||||||||||||||

| New Design Features: | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| TECHNICAL SPECIFICATIONS: | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| Cone Mill: | ||||||||||||||||||||||||||

| Application & Process: | ||||||||||||||||||||||||||

Table top Laboratory Cone Mill is used for wet granulation in pharmaceutical industry, pharmacy colleges and R&D institutions and for research and development of pharmaceutical products. It is a self contained portable unit useful for granulating, mixing and size reduction. The Cone mill operates on the principle of Rubbing force by cone blade and rotating within a selected cone screen to get the required size reduction. The material is fed in the hopper, shredded and milled through cone blade consisting of Cone Blade and Cone Sieve. The rotation speed and direction of cone blade could be adjusted through control panel. The material then passes in discharge hopper through the cone screen in gravity force which helps keeping the temperature low and avoids chocking of material during the process. The material is collected in the container placed under the hopper. In cone mill particle size reduction is done through rubbing of material by cone blades moving at high speeds, inside a cone sieve. | ||||||||||||||||||||||||||

| New Design Features: | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| TECHNICAL SPECIFICATIONS: | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| Comminuting Mill: | ||||||||||||||||||||||||||

| Application & Process: | ||||||||||||||||||||||||||

PRISM Lab Scale Comminuting Mill has been designed for wet and dry granulation, pulverizing and dispersion of products for pharmaceuticals, chemicals, Cosmetics, Confectionery, Fertilizers, Insecticides, Detergent and food industries etc. Built on advance engineering principles the machine consists of Hopper, throat hopper, processing chamber, beater assembly, sieve, heavy duty motor, overload starter, back frame and rigid structure with castors. The comminuting chamber having simple to use features, the reversible comminuting chamber having simple to use features, the reversible comminuting chamber consists of blades with knife and impact edges. The knife edges come in use for granulating, chopping, cutting and sizing while impact edges are preferred for grinding, pulverizing, blending and mixing. The dynamically balanced rotor mounted on pillow back at outside of the chamber with effectively sealed in a fabricated housing. | ||||||||||||||||||||||||||

| New Design Features: | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| TECHNICAL SPECIFICATIONS: | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

|

DRY GRANULATION

| ||||||||||||||||||||||||||||||||

| 1.Roll Compactor: | ||||||||||||||||||||||||||||||||

| Application & Process: | ||||||||||||||||||||||||||||||||

| The NewLABORollercompactor machine is used for dry granulation of pharmaceutical ingredients in pharmaceutical industry, in food as well as chemical industry for densification and granulation of powder. The dry compaction of the powder between two rollers on high pressure for increased bulk density, making granules, dust free processing and reducing packing size. The material in form of powder passes through the two counter rotating rolls of roller compactor under very high pressure. As the volume decreases through the region of maximum pressure, the material is formed into a solid compact sheet or flakes of ingredients. These flakes or compact sheet of ingredients are reduced in size to obtain the desired grain size. The machine takes extra care to prevent the generation of fine during this process. | ||||||||||||||||||||||||||||||||

| New Design Features: | ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

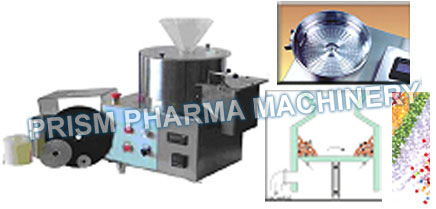

| Oscillating Granulator: | ||||||||||||||||||||||||||||||||

| Application & Process: | ||||||||||||||||||||||||||||||||

The Laboratory Oscillating granulator is for wet and dry granulation widely used in research laboratories of pharmaceutical, food and chemical industries. Product is charged from the top through in feed hopper and material falls on the rotor lades. The particles are broken by a set of oscillating bars arranged in cylindrical form over a screen of suitable mesh. Due to the knife edges mounted on rotor, the downsizing of particle takes place and through sieve material gets pushed outward from the bottom opening. | ||||||||||||||||||||||||||||||||

| New Design Features: | ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| TECHNICAL SPECIFICATIONS: | ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

|

pallets-making

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| Application & Process: | ||||||||||||||||||||||||

The prism compact NewLABOextruder high precise technology is mainly used in pharmaceutical, chemical, Agro chemical and food industries. Featuring mechatronis and confirming to the requirement of cGMP. It is a high efficiency, energy saving, safe and clean equipment for convert mixed dough to fixed diameter extrudes/ needles. The Lab Extruder Equipment has two major parts one is the die screen of required size and other is pressing screw, needles coming out of the extruder are cut into definite length by cutter blade. The size of sieve can very from 0.5 to 5 mm hole size. For conversion into spherical spheres/pellet a Spher’oidizer needs to be used conjunction with the extruder. | ||||||||||||||||||||||||

| New Design Features: | ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| Application & Process: | ||||||||||||||||||||||||

The prism compact NewLABOspher’oidizer high precise technology is mainly used in pharmaceutical, chemical, Agro chemical and food industries. Featuring mechatronis and confirming to the requirement of cGMP. It is a high efficiency, energy saving, safe and clean equipment for convert needles from extruder to fixed size of the pellet formed. The Lab Spher’oidizer Equipment has chequered plate rotating at variable speed, the design of the plate depends on the size of pellets being processed in the drum. A Layering equipment used for drug loading and coating application is a modification of spher’oidizer with different plates and nozzle option. | ||||||||||||||||||||||||

| New Design Features: | ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| 3.Palletizer: | ||||||||||||||||||||||||

| Application & Process: | ||||||||||||||||||||||||

Palletize is implemented in the pharmaceutical, agricultural, chemical, nutraceutical industries where it is required to create pellets with uncontrolled characteristics of density, size, and surface. These technologies are implemented in multiple industries with very specific differences required for pharmaceutical batch systems and continuous systems. The Process powder is put on the inclined cylindrical drum and they are converted into round pellets with the help of the cylindrical drums. The inclined cylindrical drum is rotate inclined and spray nozzle is fitted for fluidized / spraying of water/ binder. Due to round baffles the powder is fluidized and agglomeration and also that time fluidized the water/ binder by spray nozzle. Due to rotation of drum agglomerated granules is rotate in the drum during the pelletization process. During this movement of pellet on the rotating drum, they are get bigger size by the fluidization on the drum and converted into approximately same size of its diameter 2mm to 6 mm. Wet Pellets are turned into spherical shape by rotating. | ||||||||||||||||||||||||

| New Design Features: | ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| TECHNICAL SPECIFICATIONS | ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

|

FLUDIZED GRANULATION & PALLET COATER

| ||||||||||||||||||||||||||

| 1. Fluid Bed Equipment - Combo | ||||||||||||||||||||||||||

| Application & Process: | ||||||||||||||||||||||||||

The prism compact NewLABOgranulatorcoater-COMBO model Fluid bed technology is a offer an effective and efficient method for drying, granulating, agglomerating and granules/ pellet coating. The Fluid Bed Equipment has universal application. You can combine with mixing as a very rapid dryer in combo with suitable nozzle system a combined granulator, dryer and coater. The overall concepts of the NewLABOgranulatorcoater-COMBO steam from similar of process based on production model and common needs of consistent processing and ease for operation and cleaning. | ||||||||||||||||||||||||||

1. The Drying process: Warm air is blown through a perforated distributor to rapidly and gently dry materials until the required residual moisture content is reached. Moisture evaporated from product is exhausted with drying air. | ||||||||||||||||||||||||||

2. The Granulating by Top Spraying System: The top spray granulator agglomerates finer particles into larger, free flowing granulates in a one pot process. Ingredients are mixed and pre-heated by an upward flow of heated air. Granulation occurs by spraying liquid into the fluidized powder. The granules are subsequently dried with heated air. The top spray granulator can also used for top spray coating, layering from liquids, and instantizing. | ||||||||||||||||||||||||||

3. The Coating by Bottom Spraying: Wurster System: A bottom sprays apparatus capable of the controlled application uniform layers of solid onto small to medium sized particles without agglomeration. Movement of both hot air and product is controlled by the apparatus to ensure that the heating in the process air is used for vaporization of the liquid and not undesirable heating of the product. The objects being processed are coated and dried in the coating column means wurster coater, and return to the bed in a non tacky condition for another layer of coating. | ||||||||||||||||||||||||||

| New Design Features: | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| Safety Features: | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| TECHNICAL SPECIFICATIONS: | ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

| ||||||||||||||||||||||||||

|

Subscribe to:

Posts (Atom)